HDPE sekoti leboteng matsoelintsoeke phala line tlhahiso

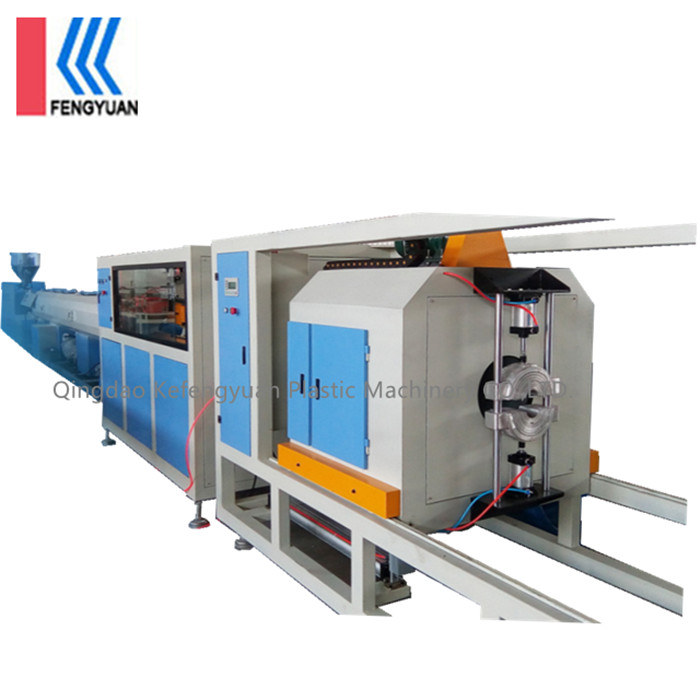

Mohala oa extrusion o entsoe ka theknoloji e ntle mme ho sebelisitsoe theknoloji e 'maloa e nang le tokelo ea molao ea k'hamphani ea rona.Lebelo le phahameng le boleng bo botle ba extrusion ka ho amohela lihlopha tse peli tsa screw extruder e nang le ts'ebetso e phahameng haholo.Moralo o ikhethileng oa "die-head" e kopantsoeng bakeng sa ts'ebetso ea lipeipi tse nang le bophara bo boholo ka katleho e phahameng ea tlhahiso.Boleng bo phahameng ba phaephe e tsoelipanang e hlahisoang ka ho amohela mokhoa o ikhethang oa matsoeli.Mochini oa ho itšeha o ka khetha mochini o le mong oa ho itšeha kapa mochini o sehang oa khoele le mochini o kopaneng oa ho sila, o nang le tiiso e ntle le ntlha e phahameng ea polokeho.Likarolo tsohle tsa mohala oa tlhahiso li tsamaisana ka tumellano e phethahetseng, ts'ebetso e bonolo le ts'ebetso e phahameng ka ho amohela sistimi e tsoetseng pele ea taolo ea PLC e nang le touch LCD.

Sehlahisoa se seholo

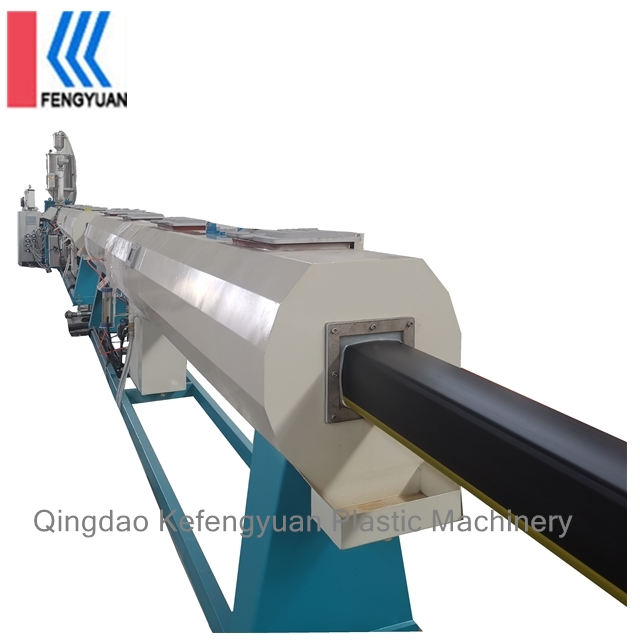

Sesebelisoa se phahameng sa "screw extruder" se nang le tekanyo e nepahetseng ea bolelele ba bophara se na le melemo ea tlhahiso e kholo, polasetiki e ntle le bophelo bo bolelele ba ts'ebeletso.

Co-extruder

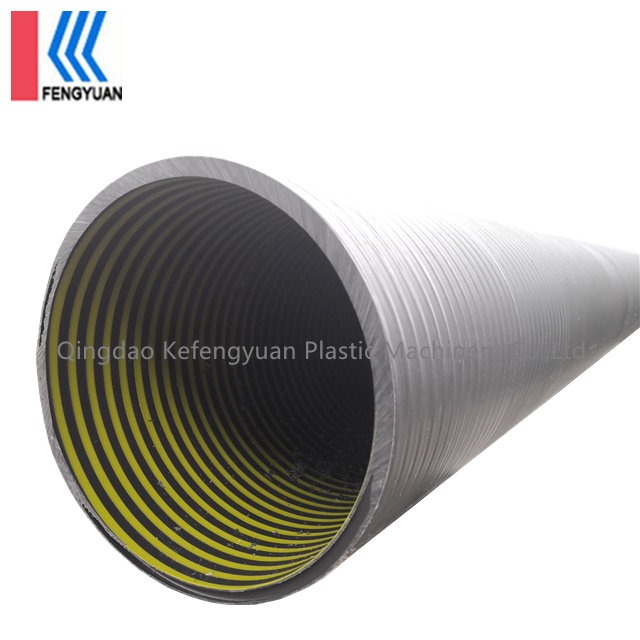

E sebelisetsoa ho hlahisa liphaephe tse ka hare tse koahetsoeng ka hare kapa tse ka ntle tse nang le mebala e 'meli le mebala e mengata ho etsa hore liphaephe li be ntle le ho tšoarella nako e telele.

Extrusion Die-head

Sebopeho sa Spiral shunt, sebelisa tšepe 40Cr, Ka ho qhekella, ho tima le ho halefa.Ts'ebetso ea kanale ea phallo ke plating e thata ea chromium le ho bentša.

Tanka ea vacuum le tanka ea ho futhumatsa metsi

Moralo oa mabokose a mahlale ka ho fetesisa le litlhophiso tsa ho fafatsa ka hohle-hohle li etsa hore ho pholisoe le phello ea sebopeho e fihlele molemo ka ho fetisisa.

Mochini oa ho futhumatsa

Lebelo la phetisetso le laoloa ke mananeo mme pina e tsamaisoa ke servo motor ho etsa hore ts'ebetso e tsitsa.

Mochini o fefolang moea

Mochini o tsoelipanang o amohela motsoako oa bokahohleng, o ka khethoang ka rolara e kentsoeng ea matsoelintsoeke kapa rolara e ka senyehang.E ka hlophisoa ka mokhoa o feto-fetohang ho ea ka litlhoko tsa sebopeho sa workshop, ho kenyelletsa le litepisi, li-extruder tsa gluing le lik'habote tsa taolo.

Stacker

Ka phetoho ea motlakase le ea matsoho, tokiso e nepahetse haholoanyane.

Sistimi ea taolo ea motlakase

Ho sebelisoa PLC ea Siemens, lisebelisoa tsa motlakase ke Schneider le Siemens, sesebelisoa sa ho laola mocheso ke Omron, 'me converter ea maqhubu ke ABB le Fuji.